Vapour Blasting Service based in Crawley, Sussex

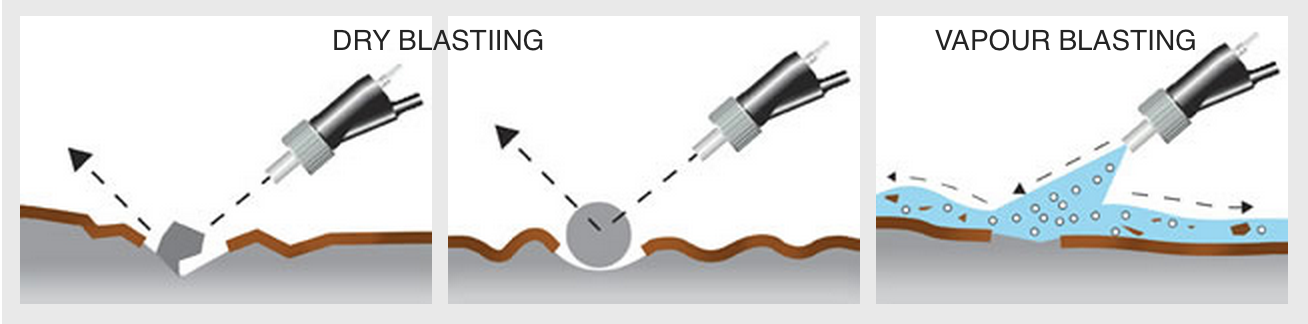

Vapour Blasting is a process also known as wet blasting, or

aquablast cleaning. The Vapour Blast process involves 3 basic

components, a slurry consisting of glass beads and water with

compressed air providing the motive force. No hazardous or

toxic chemicals are used. The process takes place inside of a

purpose built blasting cabinet which utilizes a recirculation

pump to maintain the slurry in suspension.

A hand held spray nozzle which receives a continuous supply

of the slurry is the mixing point where the slurry and compressed

air come together, exiting in a high velocity vapour. It

is this vapour that performs the cleaning action, resulting in a

“like new” surface finish.

The process cleans metal surfaces without damaging, eroding or abrading the underlying base metal, making it safe for maintaining bearing fits or critical dimensions. Machined engine surfaces such as cylinder bores, milled head surfaces, or valve seats will not be affected by Vapour blasting.

Advantages of Vapour Blasting

07487 452090

info@siclonemotodesign.co.uk